Just In Time Manufacturing

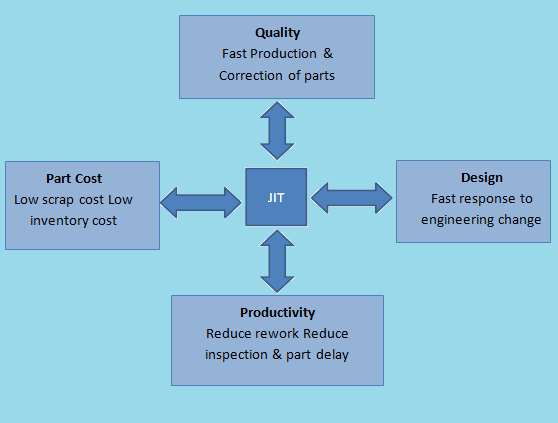

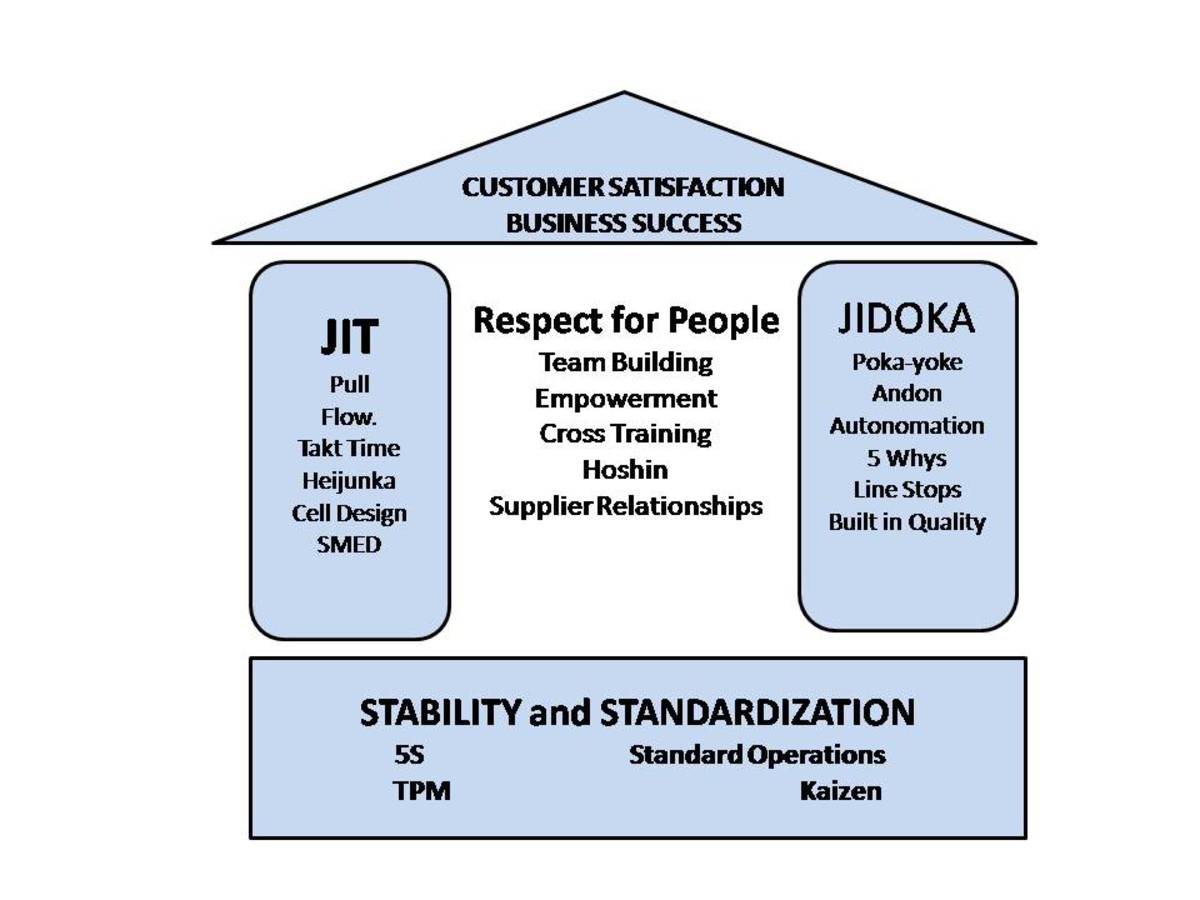

Just in time manufacturing is focused on efficiency while lean manufacturing is centered on using efficiency to add value for the customer.

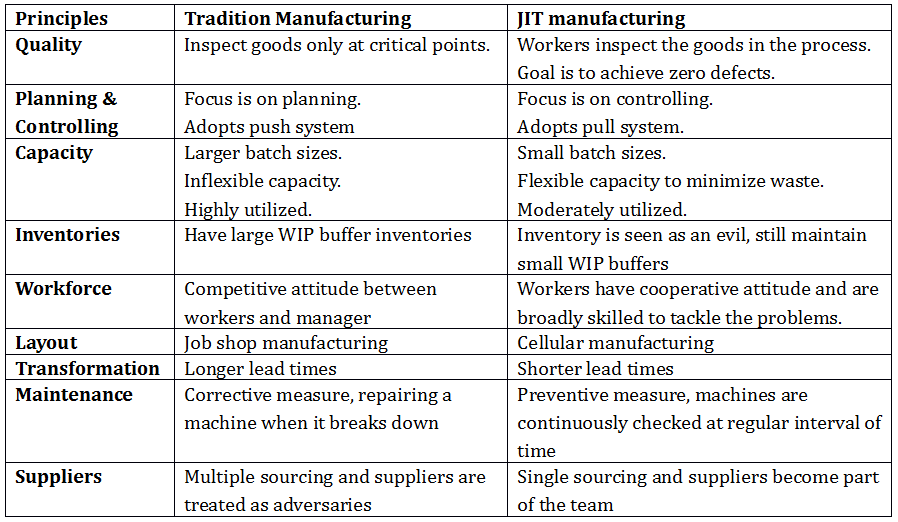

Just in time manufacturing. Just in time manufacturing was a concept introduced to the united states by the ford motor company. Jit just in time manufacturing just in time is a management philosophy and not a technique. Just in time jit is a production strategy in which a company only produces an item after a buyer has made an order therefore keeping inventories low. Its origin and development was mainly in japan largely in the 1960s and 1970s and particularly at toyota.

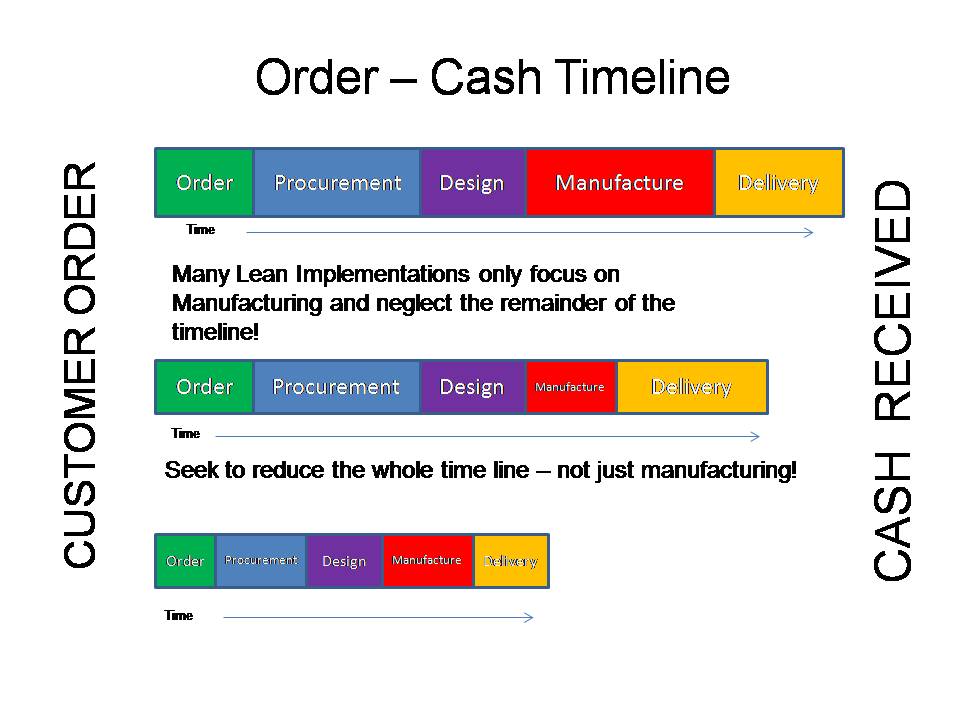

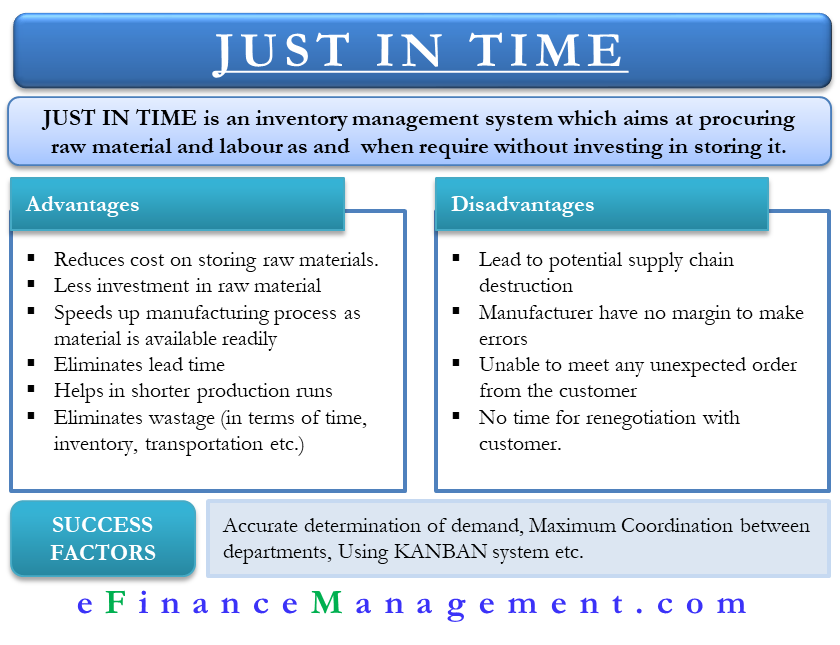

Just in time jit inventory management also know as lean manufacturing and sometimes referred to as the toyota production system tps is an inventory strategy that manufacturers use to increase efficiency. Just in time manufacturing is also known as just in time production or the toyota production system and can be defined as the methodology with an objective to reduce times within the manufacturing system as well as response times from suppliers and to the targeted customers. The process involves ordering and receiving inventory for production and customer sales only as it is needed to produce goods and not before. To elaborate further under just in time manufacturing colloquially referred to as jit.

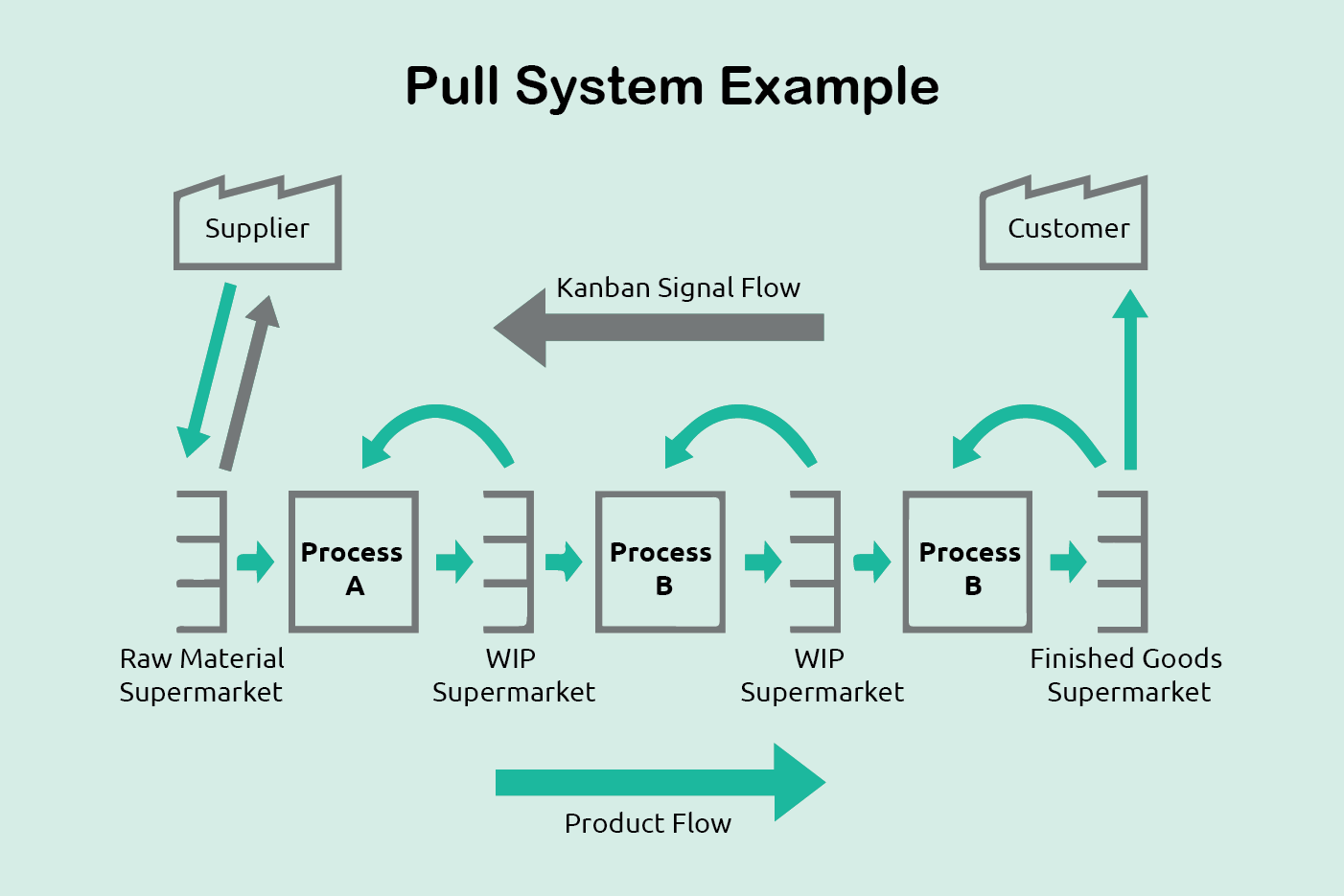

Just in time manufacturing concept is a management philosophy and not just another technique. Just in time jit manufacturing is also known as the toyota production system. It is driven by a series of signals that tell the production line to make the next piece for the product and when it is needed. Lean manufacturing takes the idea of jit and looks at it from the perspective of customer value.

Jit can be utilized on its own or as one step in the lean manufacturing process. The just in time jit inventory system is a management strategy that minimizes inventory and increases efficiency. Just in time jit manufacturing also known as just in time production or the toyota production system tps is a methodology aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. It works on a demand pull basis contrary to hitherto used techniques which worked on a production push basis.

It originally referred to the production of goods to meet customer demand exactly in time quality and quantity whether the customer is the final purchaser of the product or another process further along the production line. Just in time jit manufacturing is a production model in which items are created to meet demand not created in surplus or in advance of need.

.jpg)